Exhaust Fans

Exhaust fans are designed to remove indoor air and discharge it to the outside, allowing fresh air to enter the conditioned space. In a commercial HVAC system, refrigerant is moved by pumps, but airflow is driven by fans. Their primary purpose is to maintain healthy indoor air quality by exhausting stale, humid, hot, or contaminated air.

Why Exhaust Fans Matter in HVAC Design

- Improve Indoor Air Quality (IAQ)

They remove odors, moisture, heat, and airborne contaminants. - Maintain Pressure Balance

Commercial HVAC systems typically keep the building slightly positively pressurized, meaning the amount of exhausted air is nearly equal to the amount of supplied fresh air.- Positive pressure → Keeps outdoor contaminants from entering.

- Certain spaces require negative pressure intentionally (e.g., isolation rooms, labs).

- Support Overall HVAC Performance

Exhaust fans work alongside supply and return systems to maintain proper airflow distribution, thermal comfort, and compliance with health/safety codes.

Connection to AHU (Air Handling Unit)

- AHUs condition and distribute supply air throughout the building.

- Exhaust fans may be integrated with AHU systems or operate independently.

- In certain buildings—hospitals, labs, chemical plants—exhaust fans are required by code to remove hazardous or polluted air.

- AHUs are typically installed on rooftops, mechanical floors, or in basements.

Where Exhaust Fans Are Used + Purpose of Each Application

1) Restrooms

Removes odor and moisture → prevents mold and mildew.

2) Commercial Kitchens

Exhausts smoke, grease particles, fumes, and humidity.

3) Standard Office / Residential Buildings

A fundamental component of modern commercial HVAC systems.

4) Laboratories

Fume hoods rely on exhaust fans to remove toxic or unstable vapors.

Labs are often maintained at negative pressure to contain hazardous gases.

5) Airborne Infection Isolation Rooms (Hospital)

Negative room pressure ensures contaminated air does not escape into other patient areas.

6) Industrial Facilities

Used in ammonia plants or chemical processing environments to vent hazardous pollutants.

Also removes sawdust or particulate from sawmills.

7) Indoor Pool Areas

Exhaust fans control chemical fumes and moisture to protect air quality and prevent corrosion or mold.

Centrifugal Fans

Centrifugal fans use a rotating impeller to move air and generate high pressure, similar to how a centrifugal pump moves water. Because they can overcome greater resistance, they are commonly used in ventilation systems with complex ductwork and environments requiring strong airflow under load.

How Centrifugal Fans Work

- Air enters near the impeller hub.

- As blades rotate, air moves toward the blade tips and gains kinetic energy.

- That kinetic energy converts into static pressure before discharge.

- Air exits outward from the sides, rather than straight through the axis like an axial fan.

This design allows the fan to handle higher pressure and tougher environments.

Where Centrifugal Fans Are Used

- Commercial HVAC ducted systems

- Industrial facilities / manufacturing plants

- Systems with long or complex duct routing

- High-temperature or hazardous ventilation zones

- Example: mushroom rooftop exhaust fans on buildings

These fans are preferred where strong pressure is needed to move air across resistance.

Advantages

- Generates higher static pressure than axial fans

- Moves air faster and more efficiently in resistance-heavy systems

- Suitable for hot, abrasive, corrosive, or contaminated air

- Lower long-term maintenance (simple cleaning with vacuum)

- Offers long operating life & energy savings potential

Disadvantages

- Higher initial cost compared to axial fans

- More complex installation and setup

- Can be noisy

- Typically heavier structure

Axial Fans

Axial fans move air parallel to the fan’s axis, similar to how a propeller pushes air forward. Air enters from the direction of the shaft and leaves in the same straight direction, creating a linear airflow pattern.

They are ideal for high-volume, low-pressure applications, especially where resistance to airflow is minimal.

How Axial Fans Work

- Airflow is created by pressure differential

↳ Air moves naturally from higher pressure → lower pressure - Blades generate aerodynamic lift

↳ Air is drawn into the impeller and pushed outward along the axis - Best suited for large airflow / low static pressure environments

Typical Applications

Axial fans are commonly used in clean and ventilated spaces where a large amount of air must be moved without significant pressure loss.

| Application | Why Used |

| Clean rooms / Electronics manufacturing | No dust, high airflow required |

| Agricultural buildings (livestock / poultry) | Low pressure, large open volume |

| Greenhouses | Moves fresh air through long spaces easily |

| Warehouses, factories | General ventilation with low resistance |

Advantages of Axial Fans

- Operates quietly

- Low cost

- Easy to install

- Simple maintenance and repair

- Effective for high airflow volume

Disadvantages

- Requires more energy to operate efficiently

- Moves less volume under pressure compared to centrifugal fans

- Must be much larger to achieve similar airflow performance

Selecting the Right Exhaust Fan – Key Conditions

When choosing an exhaust fan, consider the following:

- Fan Model / Type

Different fan designs perform different jobs – selection must match use case. - Airflow Volume (CFM)

How much air needs to be exchanged per minute? - Air Properties

Temperature, humidity, contaminants, chemical levels

→ Hot air may require heat recovery system

→ Dirty air may require filtration or scrubbing (often regulated) - Static Pressure / Resistance

Measured in ductwork using a manometer

This determines required fan power and sizing. - Sound Level (Sones)

Ensure noise remains acceptable for the operating environment.

Components of an Exhaust Fan System

An exhaust fan system consists of:

- Fan + Electric Motor

- Drive System

- Flow Control Devices

This focuses specifically on impellers and blades, the components responsible for generating airflow.

Role of Impellers & Blades

- The shape and type of blades determine the fan’s performance.

- Centrifugal & axial fans are defined primarily by their wheel/impeller design.

- Blade design affects:

- Pressure capability

- Airflow volume

- Dirt resistance

- Efficiency & energy use

Centrifugal Impellers

Centrifugal blower performance is determined by blade pitch angle.

Three major types:

1) Forward-Curved Blades

- Medium pressure / High airflow

- Very efficient but not suitable for dirty air

- Used for: clean air ventilation, exhaust where air is filtered or clean

2) Backward-Curved Blades

- High pressure / High airflow

- More efficient + resistant to dirt, heat, abrasion

- Ideal for heat recovery & general extraction systems

3) Radial Blades

- High pressure / Medium airflow

- Best for dusty, moist, corrosive environments

- Typical features: 6–8 blades, thick, narrow, deep

- Least efficient of the three, but most rugged

Axial Fan Blade Designs

Axial blades range from 2 to 20+ blades depending on design.

Airflow moves straight through, parallel to the shaft.

Main blade types:

1) Propeller

- Simple, common design (like desk or ceiling fans)

- Low speed / Moderate temperature

- Lower pressure capacity

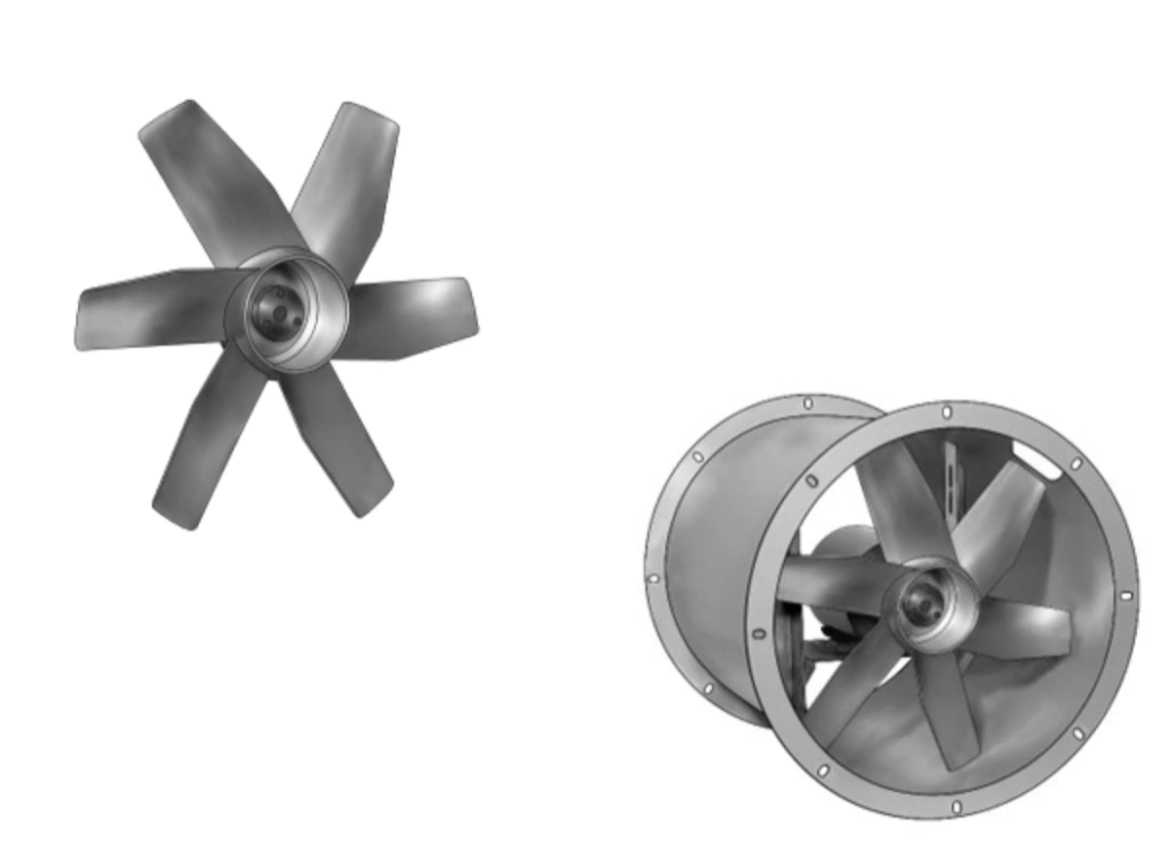

2) Tube Axial

- Propeller mounted inside a cylindrical housing

- Designed to improve pressure & efficiency

- Used for general ventilation in facilities

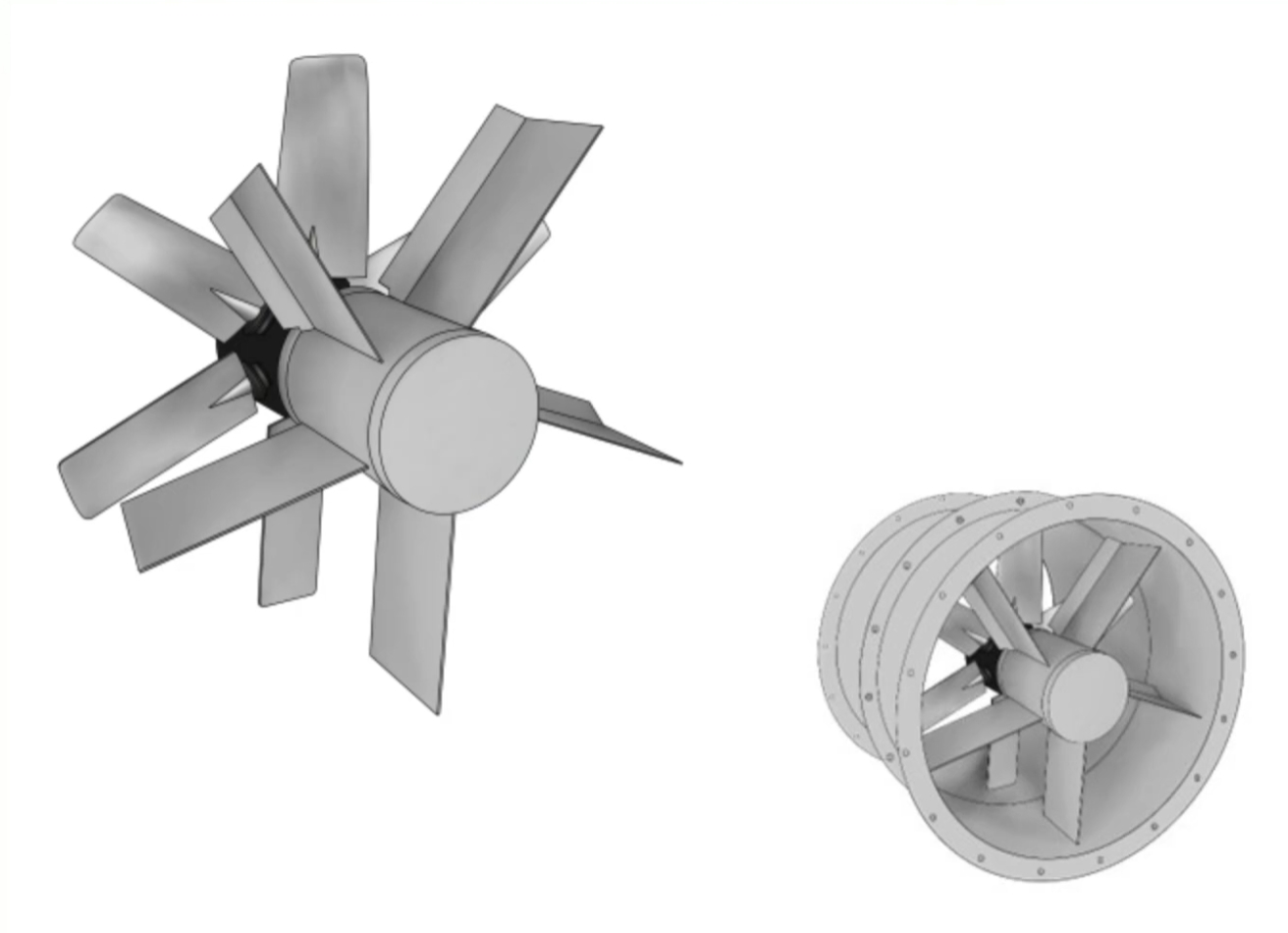

3) Vane Axial

- Tube-axial fan with guide vanes

- Vanes straighten airflow → higher pressure + performance

- Suitable for commercial and industrial use

- More energy-efficient than centrifugal fans

Additional Exhaust System Components

What Ducts Do

Ductwork provides the pathway for air movement within a commercial HVAC system.

✔ Moves conditioned air to required spaces

✔ Removes stale or contaminated air to outdoors

✔ Channels airflow to maintain comfort and ventilation targets

Ducts vary by shape, material, size, insulation, and installation method.

Rectangular Ducts

Advantages

- Flexible installation when space has height/width restrictions

- Typically requires less maintenance

Disadvantages

- Harder to seal joints → more leakage potential

- Requires more sheet metal to move the same airflow compared to round ducts

Round Ducts

Advantages

- Easier to insulate and seal than rectangular

- Requires less material → easier to install and bend

- Lower leakage due to smaller surface-to-area ratio

Disadvantages

- Requires more height clearance for installation

- Harder to clean → dust buildup may reduce efficiency over time

Duct Leakage & Debris Issues

Duct leakage or blockage can occur due to:

- Low air velocity (air moves too slowly)

- Flexible duct usage

- Poor modifications or improper connections

- Lack of cleanout access

Leakage can be reduced by proper sealing or welding duct seams.

Heat Recovery Systems (HRS)

Exhaust air may be uncomfortable or contaminated, but it still contains valuable thermal energy.

A heat recovery system allows that energy to be captured instead of wasted, improving efficiency and reducing energy cost.

How it Works

Heat exchange coils are placed inside the exhaust path → heat transfers from exhausted air → redistributed to areas where heat is needed in the building.

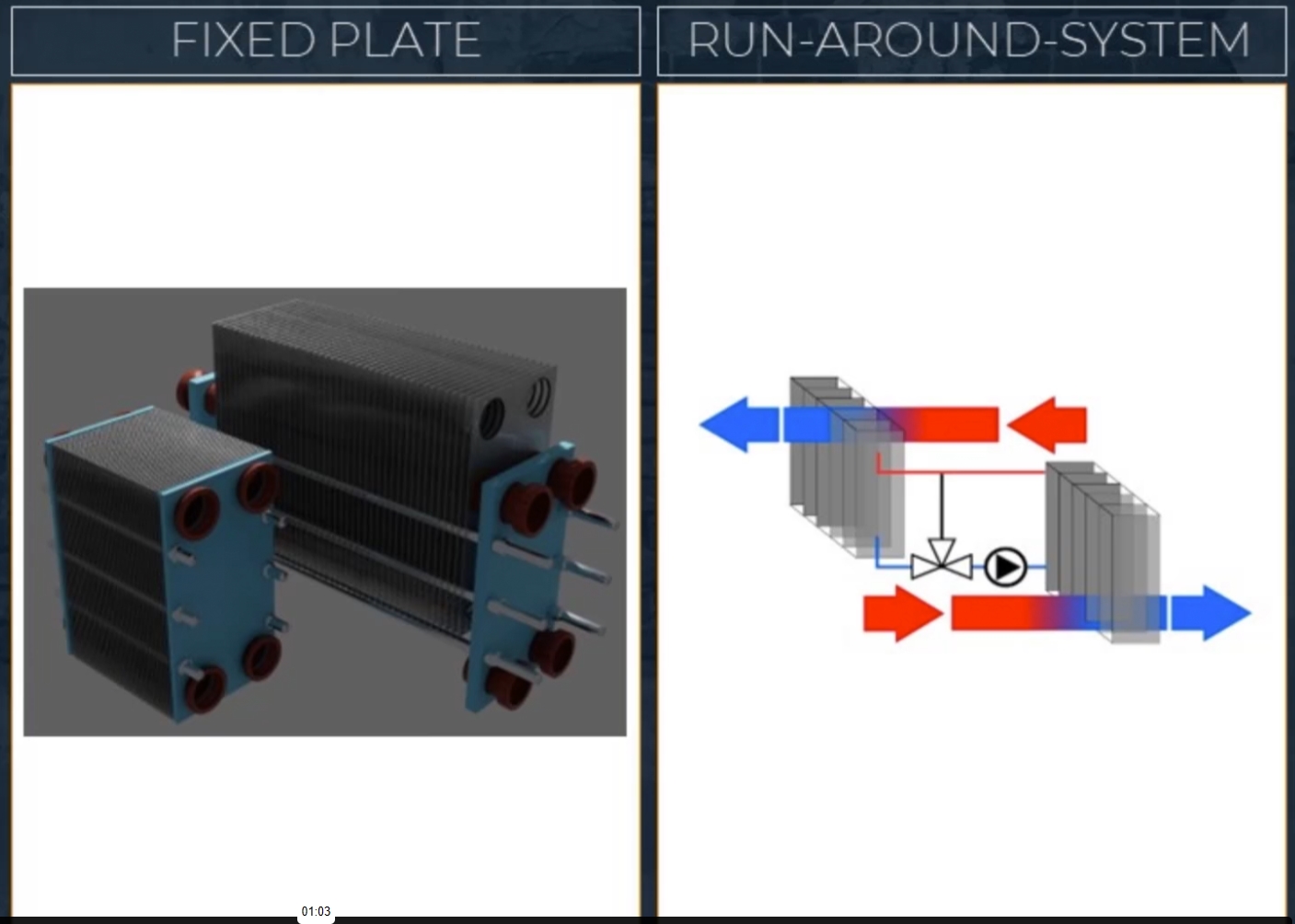

Types of Heat Recovery Systems

| Type | Key Features |

| Rotary Thermal Wheel | Compact, available in large sizes, low pressure drop |

| Heat Pipes | No moving parts (except refrigerant in the pipe), fan location flexible |

| Fixed Plate Heat Exchanger | Simple design, easy to clean, no moving parts |

| Run-around System | Supply and exhaust airstreams do not mix; physically separated |

When Not Used

- When the building is in cooling mode

- When recovered heat is not beneficial

- In some regions, HRS may be required by energy-efficiency regulations

Refrigerant Leak Detection System

Many HVAC systems rely on refrigerant, but leaks can be toxic, unsafe, and environmentally harmful.

A leak detection system ensures safety and prevents refrigerant loss.

Purpose

✔ Detect unintended refrigerant release

✔ Prevent hazardous exposure and regulatory violations

✔ Trigger early response → minimizes danger & repair time

How It Works

- Refrigerant sensors monitor surrounding air

- If a leak is detected → alarm activates

- Audible + visual warning

- System automatically starts the exhaust fan

→ removes refrigerant gas to prevent buildup - Maintenance team is alerted to find and fix the leak

'HVAC Fundamental (English)' 카테고리의 다른 글

| The Comprehensive Guide to Residential HVAC Design: From Heat Load Basics to Manual J Mastery (1) | 2025.12.21 |

|---|---|

| Residential Ductwork Fundamentals: Layouts, Materials, Fabrication, and Installation (0) | 2025.12.14 |

| What is an FCU? (0) | 2025.12.07 |

| Compressor Types: Best Use Cases (0) | 2025.06.04 |

| HVAC Thermodynamics Basics (0) | 2025.06.01 |